Rebuild and Refurbishment Services

It’s just a fact of life in the molding business – Hot Runner molds will periodically require maintenance. Sometimes they are minor fixes, while other times a major problem occurs demanding a complete system overhaul. Most of the time we don’t see the crisis looming, so when it does you need a partner you can trust to get the system back in service and producing.

LHR Technical Service provides Customers with fast, expert hot runner system rebuilds and refurbishments that get your molds back on line. Our professional staff of Service Technicians will diagnose the problem to determine the root cause of the issue and provide a realistic solution. We offer prompt Threat Assessment Evaluations to outline the problem and resolution along with a price and work completion estimate.

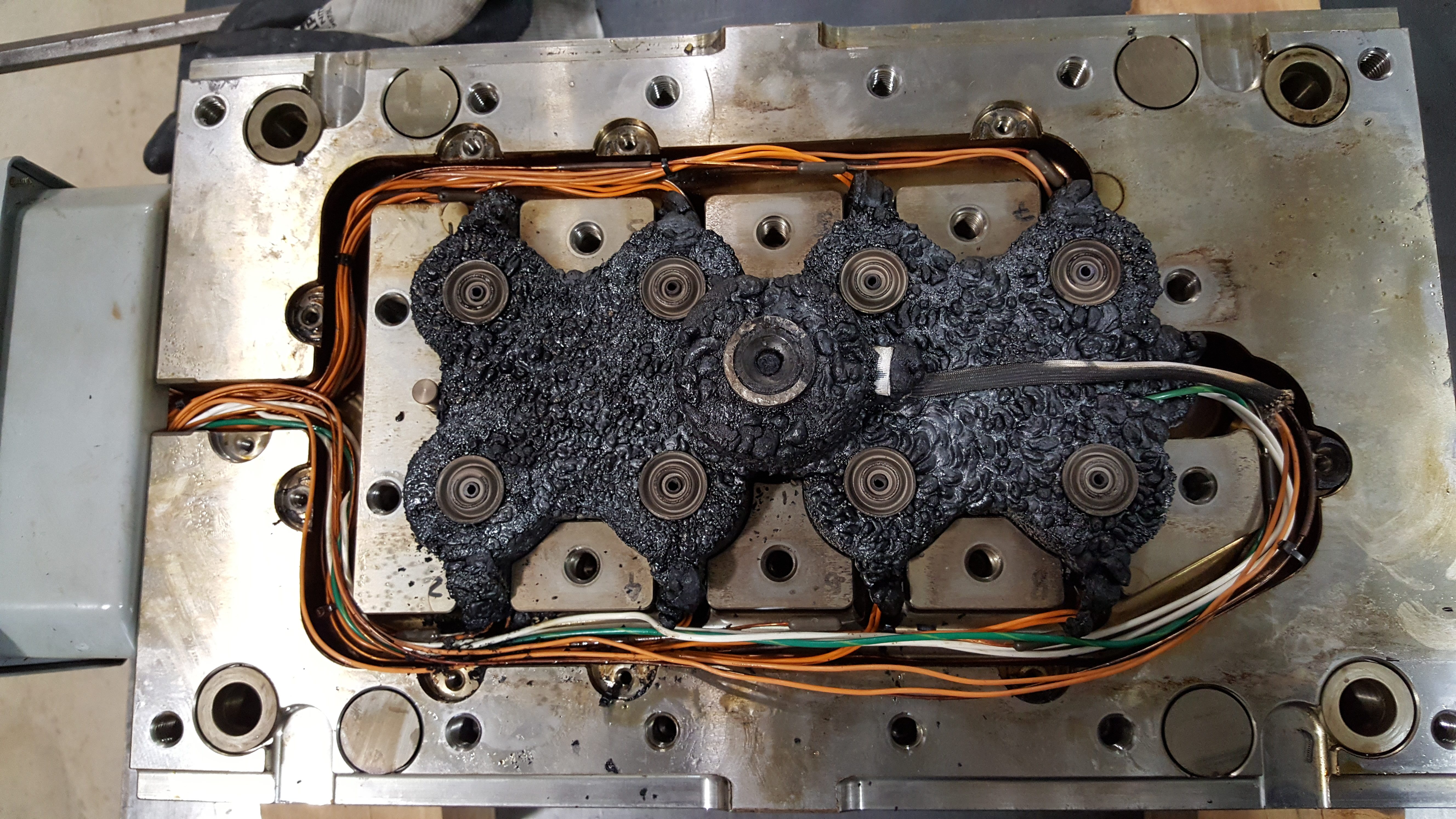

Before:

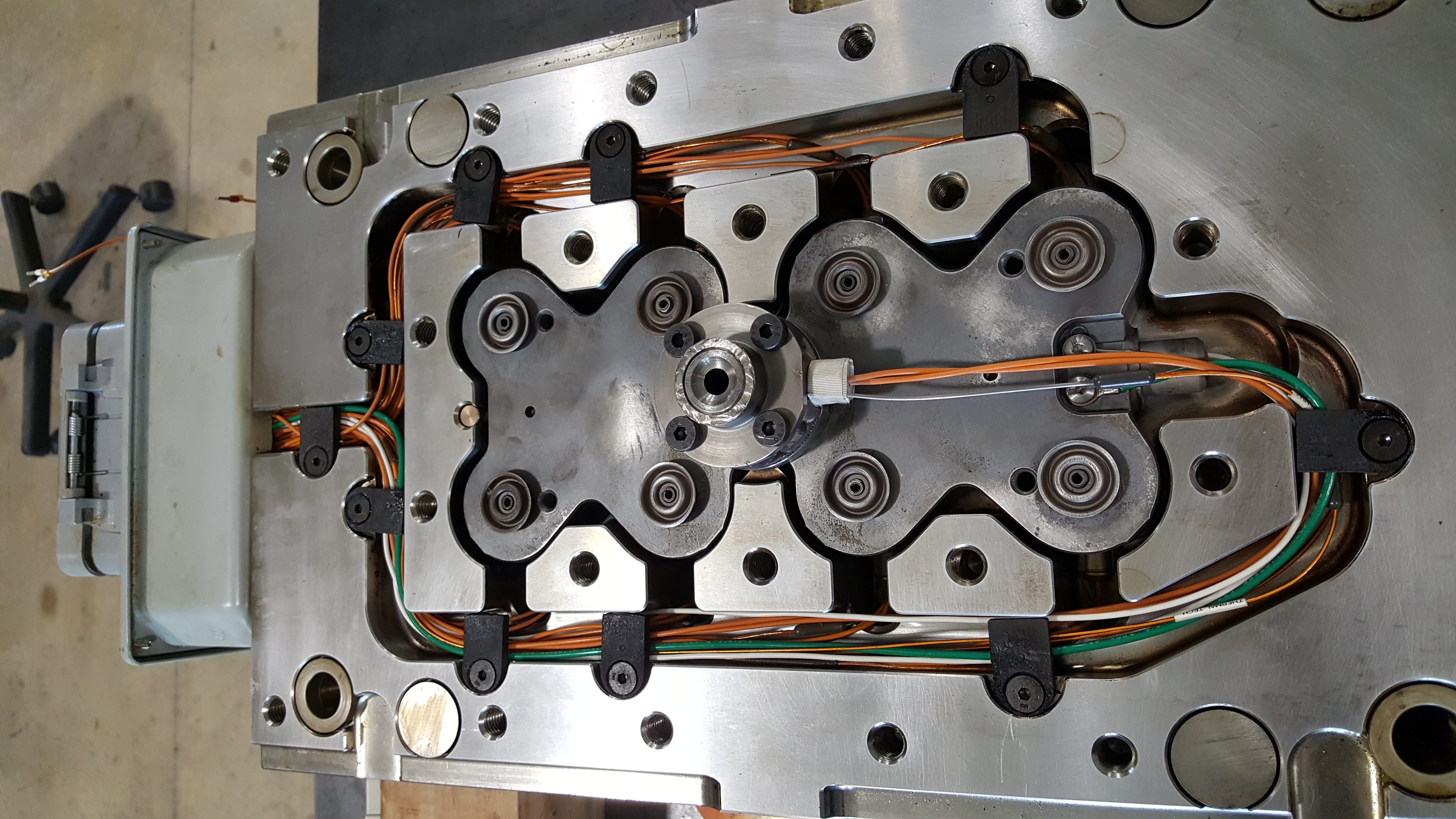

After:

LHR provides Rebuild and Refurbishment Services for all major Hot Runner System brands

- Hot Half System Rebuild – Disassembly of hot half system, clean all tool plates, perform precise measurements to ensure all plates are within specified tolerances, remove, evaluate, clean and repair all hot system components. System is reassembled and electrically tested for power and thermocouple continuity.

- Manifold Refurbishment – All Manifolds are cleaned both externally and internally so that all material is removed from melt channels. The manifold is checked for leaks and measured to ensure all specified dimensional tolerances are met. Heating elements and connections are inspected and replaced if necessary. Surface grinding is available if required.

- Nozzle Repair – Hot runner nozzles are fully inspected and cleaned to remove all resin from material tubes and tips. Tips are examined to ensure all length and tip angle geometry is within the manufacturers specification. New tips and grinding service is provided when required. All heating element and thermocouples are inspected for continuity and correct placement.

- Temperature Control Calibrations and Repair – We perform diagnostics on Gunther temperature controls and calibration to ensure accurate temperature measurements and process control. Modules and relay cards can be repaired or replaced when required. We service Control to Mold cables as well.

Call us at (815) 786-2935 for Immediate Support

Engineering and Design Support

Call us at (815) 786-2935 for Immediate Engineering Support

Download Specific Product Information and Specifications

- Complete Technology Catalog

- Product Brochures

- Case Studies

Brochure Hot-Runner Solutions For Your Industry

This brochure provides an overview of the complete range of innovative hot-runner systems, from hot runner-nozzles and valve-gate technology to manifold systems, “hot halves“ and services.

Mini Hot-Runner Systems

The small construction size and simple mould construction are convincing features in the Günther mini hot-runner systems. The nozzles with individually controlled tips and a nozzle length of ≥ 20 mm can be installed in very confined spaces.

Rapid-Systems

GÜNTHER Rapid manifold technology with a lot of benefits:

- Cost-effective and short delivery times

- Standard manifolds in straight and 2- and 4-cavity versions such as a cross manifold

- Now with BlueFlow® hot-runner nozzle type SHF

- Rapid-system „Basic“online configuring

- 3D-models are available for download in CADHOC® database

Nozzle Type “ET1”

Hot-runner nozzle type “ET1”, the perfect solution for high temperature applications.

Oktaflow®

Hot-runner nozzle with the OMT type is designed for the direct side gating of articles in compact, multi-cavity moulds. They allow a cost-effective mould construction, with undivided insert. The OMT type can be used with a heated adaptor as a single nozzle.

RapidFlow® Hot Half

Hot-runner systems in the form of “hot halves” for integration into your mould half with the associated mould plates. Completely assembled, cabled and co-ordinated.

Stepper Motor SMA 10

Up to 16 SMA 10 stepper motors can be controlled with high precision using the ServoControlSingle device. Needle adjustment in the range of 1/100 mm. Unrestricted suitability for clean room applications.

DP6 Controller with Fuzzy-PID Pulse Group Control

The compact controller for a cost-effective and convenient control of small hot-runner systems.

The DP hot-runner controller series has extensive functions for the reliable control of complex hot-runner systems.

Multi-Channel Temperature Controllers DPT20 – DPT45

The multiple controllers of the DPT series offer extensive functions for the safe control of complex hot runner systems.

Controller Servocontrol

With the new ServoControl we are offering a controller for all electric valve-gate actuation: electromagnetic actors, stepper motors and servo motors. The controller is equipped with the hardware components as per your requirements.

Hot Runner Systems For Medical Engineering

Pace setting developments in medical engineering are closely connected with plastic materials. Products with the most varied properties meet extremely high requirements of precision and functionality. Hot runner technology plays a key role in the process of cost effictive production.

Luminous Side Lights For Trucks

Hot-Runner Technology. A new type of truck side lights consists of three different plastic materials and inserts. It is injection molded in a single-stage process. In making up the concept for the complex hot-runner system, designers had to deal with two obstacles: it had to pay account for the vast differences in temperatures between mold and material, and place the required number of eight needle valve nozzles within a restricted space, while adhering to the exacting tolerances.

High-Tech Manufacture For Infusion Solutions

B. Braun Melsungen AG, one of the Europe’s largest manufacturers, has brought a new high-tech production facility for infusion solutions on stream. Needle valve technology played an important role in the implementation of the project.