New System Design

When a new part project is conceived the next logical step is to determine the most efficient means to mold the part. There are many variables in bringing the project to the Kick-Off phase and many questions to be considered.

- What type of material will be used?

- Which mold design will yield the best part quality and the fastest cycle times?

- Can I use a Hot Runner System to reduce scrap and reduce cycle times?

These are important milestones in the part development and any misstep can be very costly and painful.

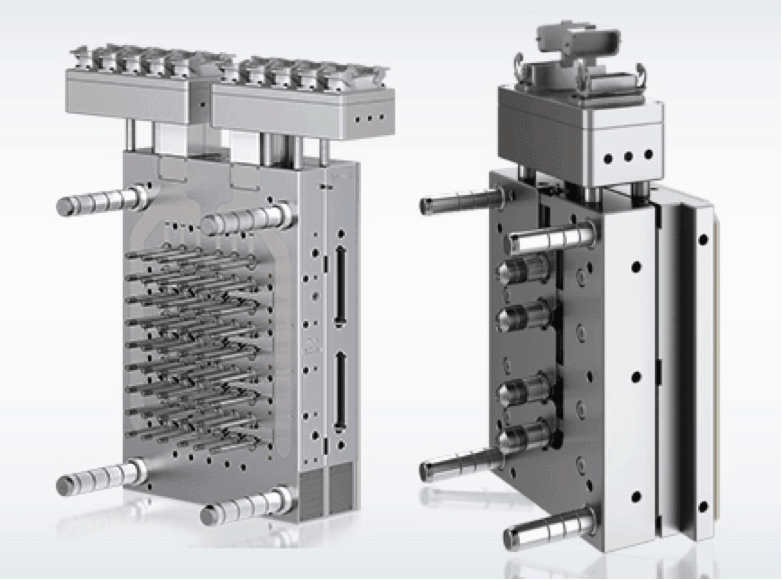

LHR has over 25 years of experience in assisting molders and toolmakers alike with designing Hot Runner Systems that are guaranteed to perform. LHR is the exclusive North American Representative for Gunther Hot Runner Systems, a world-renowned manufacturer of complex hot runner systems. We excel in developing systems for highly engineered materials and small shot weights.

Your Engineering Partner for New Hot Runner System Design

- We work with both the molder and toolmaker to create a system that meets the technical, space and budget requirements for the project. We have an extensive Application Database of prior part projects that we use to predict success and act as a template for new system design.

- We use Mold Flow, Mold CAE and SIGMA-Soft FEA models and actual test molds to simulate the conditions of the proposed new part design to ensure a successful outcome.

- We provide 2D Drawings and 3D Models of all our systems for easy integration into tool designs.

- LHR will provide ongoing support as the tool design process evolves, through First Article Approval and PPAP.

- LHR will be onsite for system start-up and commissioning and runoff of new hot runner systems at your request.